Direct to Film (DTF) printing has become the go to solution for new apparel brands because it offers low setup costs, vibrant colors and flexibility for short runs. But while Direct to film looks simple on the surface, many new brands make avoidable mistakes that cost time, money and print quality.

New DTF brands often struggle due to poor artwork preparation, incorrect heat‑press settings, low‑quality films or inks and inconsistent curing. Avoiding these mistakes requires proper file setup, tested press parameters, reliable DTF supplies and working with an experienced DTF printing partner like ZapDTF.

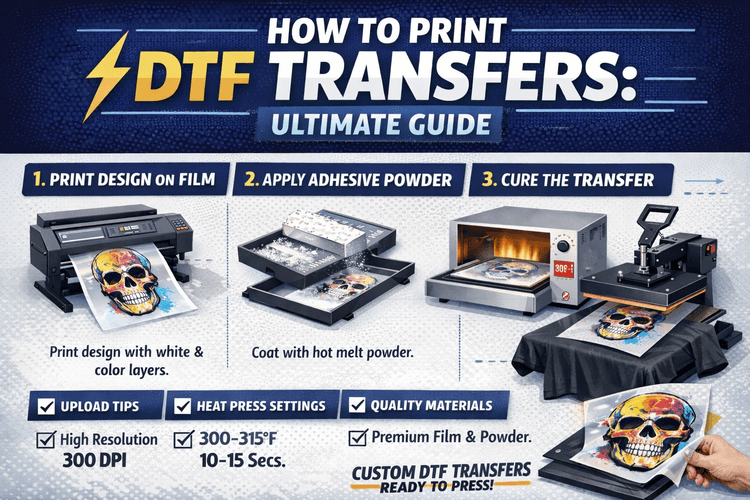

1. Using Low‑Resolution or Improper Artwork Files

The mistake

One of the biggest DTF printing mistakes is uploading low‑resolution images or incorrect file formats. Many new brands use:

- Screenshots

- Social media images

- JPG files with compression artifacts

These files may look fine on screen but print blurry, jagged or pixelated on fabric.

How to avoid it

- Always upload 300 DPI artwork at final print size

- Use PNG or vector files with transparent backgrounds

- Avoid resizing artwork after upload

ZapDTF Tip: Our pre‑press team checks files before printing and flags resolution issues early saving you reprints and wasted transfers.

2. Ignoring White Ink and Color Contrast Issues

The mistake

New brands often assume DTF prints colors the same way on every fabric. Without proper white ink underbase:

- Colors look dull on dark garments

- Fine details disappear

- Prints lose vibrancy

- How to avoid it

- Design with fabric color in mind

- Ensure proper white ink layering

- Avoid ultra‑thin lines on dark apparel

Why ZapDTF Printing helps: We calibrate white ink density based on garment color ensuring consistent vibrancy across cotton, blends and poly fabrics.

3. Incorrect Heat Press Temperature, Pressure or Time

The mistake

Even perfect DTF transfers can fail if heat‑press settings are wrong. Common issues include:

- Prints cracking after wash

- Poor adhesion

- Edges lifting

- How to avoid it

- Follow tested DTF press settings (not guesswork)

- Use consistent medium to firm pressure

- Allow proper cooling before peeling

ZapDTF standard: Every gang sheet and transfer comes with recommended press instructions based on film and adhesive type.

4. Rushing the Curing Process

The mistake

Improperly cured adhesive powder leads to:

- Weak bonding

- Transfers peeling after first wash

- Sticky or uneven textures

- Many new brands rush curing to save time.

- How to avoid it

- Cure at the correct temperature and duration

- Ensure even heat distribution

- Avoid over‑curing, which reduces flexibility

ZapDTF advantage: Our transfers are professionally cured using commercial equipment, eliminating guesswork for new brands.

5. Choosing Cheap DTF Films, Inks or Powder

The mistake

Low‑cost supplies often mean:

- Inconsistent ink flow

- Color bleeding

- Poor stretch and wash durability

- While cheap materials reduce upfront cost, they increase failure rates.

- How to avoid it

- Use tested, professional‑grade DTF supplies

- Focus on cost per successful print, not cost per sheet

Why brands trust ZapDTF: We use premium films, inks and adhesive powders designed for long‑term durability and wash resistance.

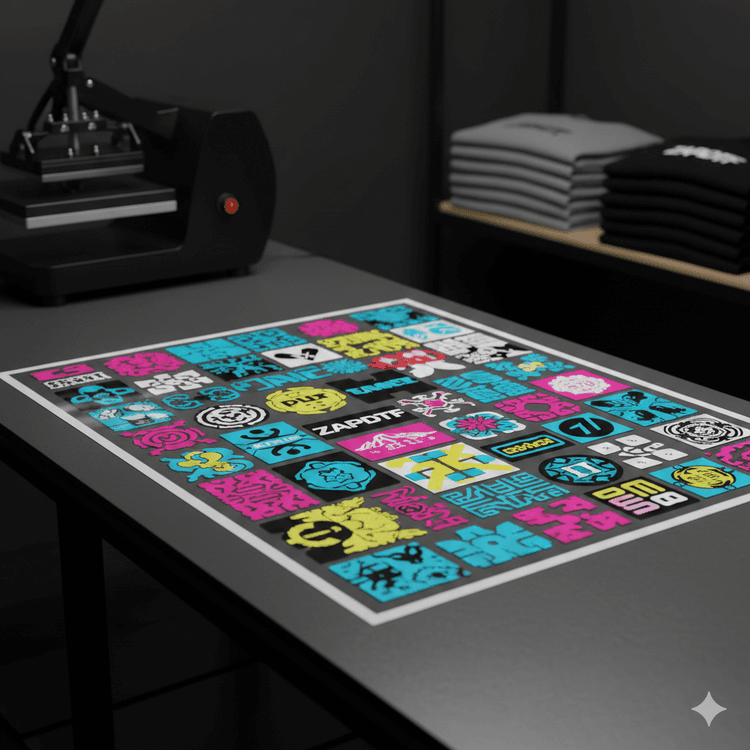

6. Overloading Gang Sheets Without Planning

The mistake

Gang sheets save money but overloading them can cause:

- Cropped designs

- Uneven pressure during pressing

- Wasted space due to poor layout

- How to avoid it

- Maintain spacing between designs

- Group similar sizes together

- Use proper gang sheet templates

ZapDTF solution: Our gang sheet service optimizes layout automatically while protecting print integrity.

7. Skipping Wash Testing Before Selling

The mistake

Many new brands sell apparel without wash testing. This leads to:

- Customer complaints

- Returns and refunds

- Brand trust issues

- How to avoid it

- Wash test every new design

- Follow proper care instructions

- Adjust press settings if needed

ZapDTF reliability: Our transfers are tested for stretch, wash durability and color fastness before shipping.

8. Trying to Do Everything In‑House Too Early

The mistake

New brands often invest heavily in DTF equipment before validating demand. This results in:

- High maintenance costs

- Learning‑curve losses

- Production bottlenecks

- How to avoid it

- Outsource DTF printing initially

- Scale in‑house only when volume justifies it

How ZapDTF supports growth: We help brands scale without upfront equipment investment, letting you focus on marketing and sales.

Why is ZapDTF the Smarter Choice for New DTF Brands?

ZapDTF Printing isn’t just a print provider, we are a production partner for growing apparel businesses. With us, you get:

- Print‑ready file support

- Consistent color and white ink control

- Fast turnaround across the USA

- Scalable gang sheet solutions

Whether you are launching your first collection or scaling nationwide, ZapDTF helps you avoid costly DTF mistakes from day one.

Conclusion

Most DTF printing problems don’t come from technology - they come from inexperience. By avoiding these common mistakes and working with a trusted DTF partner like ZapDTF, new brands can produce professional‑quality apparel, protect their reputation and scale faster.

If you want reliable DTF transfers without the trial‑and‑error, ZapDTF is built for brands that want results, not reprints.

Frequently Asked Questions About DTF Printing (FAQ)

What is the most common mistake in DTF printing?

The most common DTF printing mistake is using low-resolution or improperly formatted artwork. Poor file quality leads to blurry prints, jagged edges, and inconsistent results. Always use 300 DPI PNG or vector files at final print size.

Why do DTF prints peel or crack after washing?

DTF prints peel or crack due to incorrect heat press temperature, pressure or curing. Insufficient curing or uneven pressure prevents proper bonding. Following tested press settings and allowing proper cooling before peeling helps prevent this issue.

What temperature should DTF transfers be pressed at?

Most DTF transfers are pressed between 280°F and 320°F for 10–15 seconds using medium to firm pressure. Exact settings vary by film and adhesive, so always follow the supplier’s recommended instructions.

Can beginners do DTF printing successfully?

Yes, beginners can succeed with DTF printing by outsourcing transfers initially, using professional-grade supplies, and following proper press instructions. Partnering with an experienced provider like ZapDTF reduces trial-and-error.

Why do DTF colors look dull on dark garments?

DTF colors appear dull on dark fabrics when white ink underbase is insufficient. Proper white ink density and contrast-aware design ensure vibrant colors on black and dark-colored apparel.

How long do DTF prints last?

High-quality DTF prints can last 50+ washes when properly cured, pressed, and cared for. Wash garments inside out in cold water and avoid high heat drying to extend print life.

Is DTF better than screen printing for new brands?

DTF is better for new brands because it has lower setup costs, supports small runs, and allows frequent design changes. Screen printing is more cost-effective only for very large, repetitive orders.

Should new brands invest in DTF printers immediately?

New brands should avoid investing in DTF equipment too early. Outsourcing transfers allows brands to validate demand, reduce risk and scale efficiently before bringing production in-house.

Looking to get started? Explore our DTF gang sheets and custom DTF transfer solutions at ZapDTF.com.