DTF transfers are among the most durable apparel printing methods today, commonly lasting around 50–100 washes when produced, pressed and cared for correctly. The key difference between prints that crack in 10 washes and those that outlive the garment is material quality, heat-press technique and how customers wash and dry their clothes.

How Long DTF Transfers Really Last

DTF To Film transfers (DTF Transfer) are designed for long-term wear and can often last for years in normal use, not just weeks or months. Most reliable tests and providers report a lifespan of multiple wash cycles before noticeable fading or wear begins.

- With proper care, high‑quality and durable DTF transfers can rival or exceed screen printing durability on everyday garments.

- When stored correctly, unused dtf heat transfers can often be kept for many months and in some cases up to a few years without major loss of quality, depending on the film, adhesive and storage conditions.

For shops offering DTF Transfers for Wholesale or DTF Printing Online, setting realistic expectations “multiple washes with proper care” helps reduce complaints and returns.

What Actually Controls DTF Durability

Several technical and user-controlled variables decide whether your direct-to-film transfers crack early or stay smooth and flexible.

- Film, ink and adhesive quality: Premium PET film, stable pigment inks and high‑quality hot‑melt adhesive powder strongly improve adhesion, colorfastness and resistance to cracking or peeling.

- Fabric and use case: Smooth cotton and cotton‑poly blends typically hold DTF printing better than rough or heavily textured fabrics and high‑friction uses (sportswear, workwear) will wear any print faster.

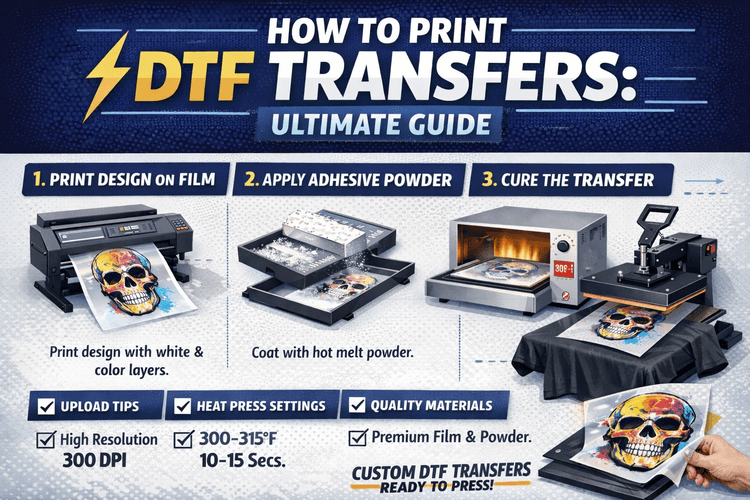

- Heat‑press settings: Ensure you use the correct temperature, pressure and dwell time. These factors are critical as improper settings are among the primary reasons why prints fail prematurely regardless of the transfer quality.

Shops that specialize in custom dtf printing in Seattle or other humid climates should also pay attention to storage: moisture and heat can degrade adhesive powder and shorten the usable life of stored transfers.

How to Make DTF Prints Last Longer

Most durability gains come from small but consistent habits during application and aftercare.

- Apply with tuned press settings

- Follow the manufacturer’s recommended time, temperature and pressure and test on your actual garment before going into production.

- Avoid under‑pressing (weak bond, early peeling) and over‑pressing (brittle prints, risk of cracking).

- Follow the manufacturer’s recommended time, temperature and pressure and test on your actual garment before going into production.

- Use best practice wash routines

- Turn garments inside out before washing to reduce mechanical abrasion on the print surface.

- Wash in cold water on a gentle cycle with mild detergent, avoiding bleach and harsh chemicals that attack the adhesive and pigments.

- Turn garments inside out before washing to reduce mechanical abrasion on the print surface.

- Dry and iron the right way

- Air‑dry when possible, or use low heat in the dryer; high heat is a common cause of premature cracking and edge lifting.

- If ironing is needed, do it inside out and avoid pressing the hot iron directly on the dtf heat transfer surface.

- Air‑dry when possible, or use low heat in the dryer; high heat is a common cause of premature cracking and edge lifting.

These simple steps are what separate “customer complaint magnets” from durable dtf transfers you can confidently ship at scale.

Common Failure Issues And How to Avoid Them

Many “DTF is not durable” complaints track back to preventable problems in the print chain, not the technology itself.

- Cracking

- Often linked to over‑curing, excessive heat or extremely high heat‑drying after washing, which can make the print brittle.

- Poor stretch management on highly elastic garments or using low‑quality adhesive powder can also contribute.

- Often linked to over‑curing, excessive heat or extremely high heat‑drying after washing, which can make the print brittle.

- Peeling or lifting at the edges

- Common when pressure is too low, temperature is off or the press time is shortened to speed up throughput.

- Overloading the washer or mixing printed garments with rough items (like heavy zippers) increases edge wear over time.

- Common when pressure is too low, temperature is off or the press time is shortened to speed up throughput.

- Fading and dullness

- Repeated hot washes, aggressive detergents and bleach are the biggest drivers of color loss in DTF Printing.

- Inks that are not specifically formulated for DTF or poorly stored transfers can also fade sooner.

- Repeated hot washes, aggressive detergents and bleach are the biggest drivers of color loss in DTF Printing.

Building clear, simple care cards into your DTF Transfers for Wholesale orders drastically reduces these issues for your end customers.

Why Choose ZapDTF for Durable Prints (Seattle & Online)

For brands, creators and print shops, the provider you choose is just as important as your washer settings when it comes to how long prints last.

- Optimized for durability first

- A professional DTF partner focuses on matched films, inks, and powders plus dialed‑in curing profiles, so you get transfers that are built for multiple washes when properly cared for.

- This lets your apparel feel consistent whether you reorder small runs or leverage DTF Transfers for Wholesale volume.

- A professional DTF partner focuses on matched films, inks, and powders plus dialed‑in curing profiles, so you get transfers that are built for multiple washes when properly cared for.

- Local and online flexibility

- If you are looking for Custom DTF Transfers in Seattle, a local‑aware partner reduces shipping time and handles climate‑aware storage and packing.

- For remote brands, DTF Printing Online gives you the same pro‑grade direct to film transfers, ready to press on demand wherever your shop is located.

With the right supplier, application process and care routine, your DTF Transfers can become a long‑term asset for your brand instead of a short‑term risk.