In Canada’s competitive printing market, UV DTF printing offers businesses a fast, durable and versatile way to deliver high-quality custom transfers across diverse materials. Understanding its core process of UV DTF transfers optimization that can help your company reduce costs and boost production efficiency. Here you will get the essential insights that help you assess the value of UV DTF technology for your business.

What is UV DTF Printing and Why Does It Matter?

Ultraviolet Direct to Film ( UV DTF) printing is a transformative digital printing method that uses UV-curable inks applied directly to a special transfer film. The ink is instantly cured with UV light resulting in vibrant, scratch-resistant, and water-resistant designs that maintain their brilliance even under demanding conditions. Unlike traditional DTF, UV DTF printing works exceptionally well on both flexible and rigid surfaces like metal, glass, plastic, wood and more.

The resulting UV DTF transfers are custom decals ready to adhere to a wide range of substrates. This technology opens opportunities in promotional products, personalized gifts, branding and industrial applications offering superior adhesion and color fidelity.

UV DTF Printing Process

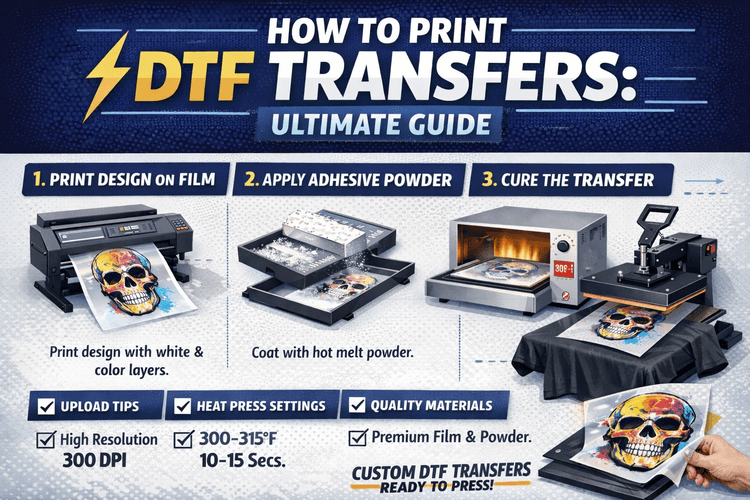

The secret to maximizing UV DTF printing lies in mastering its workflow. Here is a breakdown:

Design Preparation: Start with a high-resolution digital design which is optimized for UV printing. Professional UV DTF gang sheet builder software helps arrange multiple designs in one layout, maximizing material use and minimizing waste.

Film Loading: Specialized UV printing transfer film is loaded into the printer. This film serves as the base, holding the cured ink once printed.

Printing and UV Curing: The printer applies layers of UV-curable inks including white ink for opacity if needed. The UV light cures the ink instantly on the film, locking in colors with exceptional clarity and durability.

Lamination: Once printing and curing are done, the transfers are laminated to protect the print and facilitate smooth adhesion during the UV DTF application.

Application: The custom UV DTF gang sheets or individual transfers are then carefully transferred onto the final product surface, often using heat or pressure techniques, revealing vibrant, professional-grade designs.

The Role of the UV DTF Gang Sheet Builder

Efficiency is crucial in UV DTF printing. The UV DTF gang sheet builder streamlines production by enabling the upload and arrangement of multiple designs into a single gang sheet. This method conserves transfer film and speeds up printing cycles. Custom UV DTF gang sheets provide the flexibility to fulfil bulk DTF orders or diverse custom designs economically.

Benefits of UV DTF Printing

Adopting UV DTF printing provides several advantages:

Broad Material Compatibility: Suitable for a wide array of materials and substrates.

Enhanced Durability: Printed transfers withstand environmental wear and maintain visual appeal.

Immediate Ink Curing: UV light instantly hardens ink, expediting production timelines.

Cost-Effective: UV DTF gang sheet technology reduces material waste and production costs.

Final Thoughts

Whether you are a print shop ready to expand your capabilities or an entrepreneur entering the personalized printing market in the USA. UV DTF printing offers a powerful combination of quality, speed and versatility. By understanding and harnessing the fundamentals from mastering UV DTF transfers and printing films to leveraging custom gang sheet layouts - you position your business to meet the growing demand for high-quality custom transfers in today’s market.

Elevate your offerings with UV DTF printing and deliver premium, durable DTF prints that keep your customers coming back.